Services

Structural response

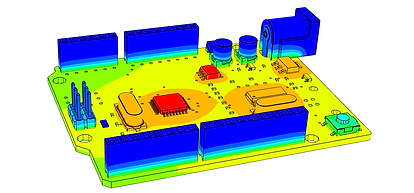

Simulations can be performed in both linear and non-linear settings to analyze deformation. Linear simulations assess small, recoverable deformations, while non-linear simulations capture large, permanent deformations once the material exceeds its elastic limit. This approach helps identify both elastic behavior and non-linear plastic deformation until the material reaches its maximum strength, beyond which failure analysis is required.

Polymer simulation

In addition to metals, understanding the viscoelastic and hyperelastic properties of polymers is crucial, as they can relax over time and undergo significant deformation without failure. These behaviors must be accounted for in simulations using advanced material testing techniques.

While metals typically fail in a ductile manner, polymers may crack or fracture under stress. Our simulations can predict these failure modes, helping to identify potential cracking points before they occur, as illustrated in the image.

Highly non-linear problems

Non-linear structural simulations account for complexities such as material non-linearity (where material properties change with stress or strain), geometric non-linearity (significant deformations or large displacements), and boundary condition non-linearity (non-linear supports or contact interactions).

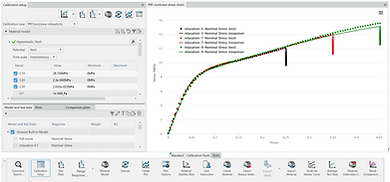

Carbon-fiber optimization

Carbon Fiber Reinforced Polymer (CFRP) Materials are subjected to various uncertainties during manufacturing and engineer can usually only have approximations regarding stiffness and strength along different directions. Optimization algorithm is employed to find the set of parameters that better validate experiments.